Growth Trajectory of the Chinese Laser Cutting Sector

Jack Ma explained that business opportunities exist where people express their dissatisfaction. The current global manufacturing industry finds its opportunities through the areas where customers file complaints. The Chinese laser cutting machine market has become a major competitor for Western manufacturers who want affordable high-performance machinery.

The fast industrial growth of China requires better metal processing equipment to support its automotive and rail transit and construction machinery sectors. Chinese factories have evolved from basic manufacturing facilities into centers that drive technological advancement.

The export market continues to show strong growth. The Made in China 2025 program along with tax benefits for high-end manufacturing exports enables suppliers to expand their sales into European markets and Southeast Asia and North America with increased confidence. The government’s smart factory initiative enables domestic suppliers to develop into worldwide competitors.

Technological Advancements in Chinese Laser Systems

Fiber lasers have transformed precision cutting operations through their ability to require less maintenance while delivering better energy efficiency than CO₂ lasers. The bed consists of honeycomb carbon structure which undergoes aging annealing treatment before being made from aviation aluminum casting. The entire bed structure uses welding techniques to create an extremely strong and stable framework which enables the machine to operate at 110m/min speed. The design approach enhances both precision and operational velocity.

Export Landscape and Global Reach

The Chinese suppliers of laser cutting machines now dominate the regulated markets of Germany and Italy and France. The main reason for their market success stems from their machines being 30–40% cheaper than Japanese and German equivalents.

Overview of Key European Safety and Quality Standards

Chinese laser cutting machine suppliers need buyers to verify the authenticity of CE marking during their evaluation process. The certification process demonstrates that products fulfill all requirements from essential EU directives including:

- EN ISO 12100: Focuses on risk assessment and safety principles in machine design.

- EMC Directive (2014/30/EU): Ensures electronic equipment does not emit harmful electromagnetic interference.

- EU Machinery Directive (2006/42/EC): Applies to all mechanical equipment sold in the EU.

The standards directly affect workplace safety and enable businesses to access legal markets.

Implications for Machine Performance and Workplace Safety

The requirements for CE compliance create more than administrative challenges because they directly affect how operations run on a daily basis. The EN ISO standards guide manufacturers to create machines with improved safety features including emergency stop mechanisms and enhanced interlocks. The design of these machines decreases the number of system failures which occur because of wear during extended operation periods.

Competitive Advantage in the Global Market

The EU requires all imported machines to meet specific standards because buyers who bring in non-compliant equipment will become legally responsible. Chinese machines that meet certification standards help businesses navigate customs procedures more efficiently while minimizing their insurance risks. B2B buyers experience simplified procurement processes through this certification system.

The integration of Industry 4.0 tools through OPC UA compatibility and remote monitoring dashboards enables Chinese machines to achieve a competitive advantage in the future market.

Key Types of Laser Cutting Machines

Fiber Laser Cutting Machines

The metalworking industry uses fiber lasers as their primary choice because of their specific advantages.

- Speeds up to 110m/min

- Capable of cutting carbon steel up to 25mm and stainless steel up to 20mm

- Energy-efficient operation with low heat distortion

The tool operates within a size range of 0.5 to 25mm for carbon steel and 0.5 to 20mm for stainless steel.

These machines operate best for manufacturing operations which produce elevator panels and kitchen equipment.

CO2 Laser Cutting Machines

The non-metal industries that use CO₂ lasers include advertising displays and textile production and acrylic signage manufacturing. The laser system provides affordable metalworking solutions to small businesses which work with lightweight materials.

Hybrid Laser Systems and 3D Laser Cutters

The combination of CO₂ for plastics and fiber for metals in hybrid platforms enables flexible production across different manufacturing lines which benefits contract manufacturers. 3D laser cutters operate in specific markets that require automotive chassis trimming and aerospace skin fabrication because they provide multi-axis precision.

Top 10 Chinese Laser Cutting Machine Suppliers with European Standards

1. WiseCut

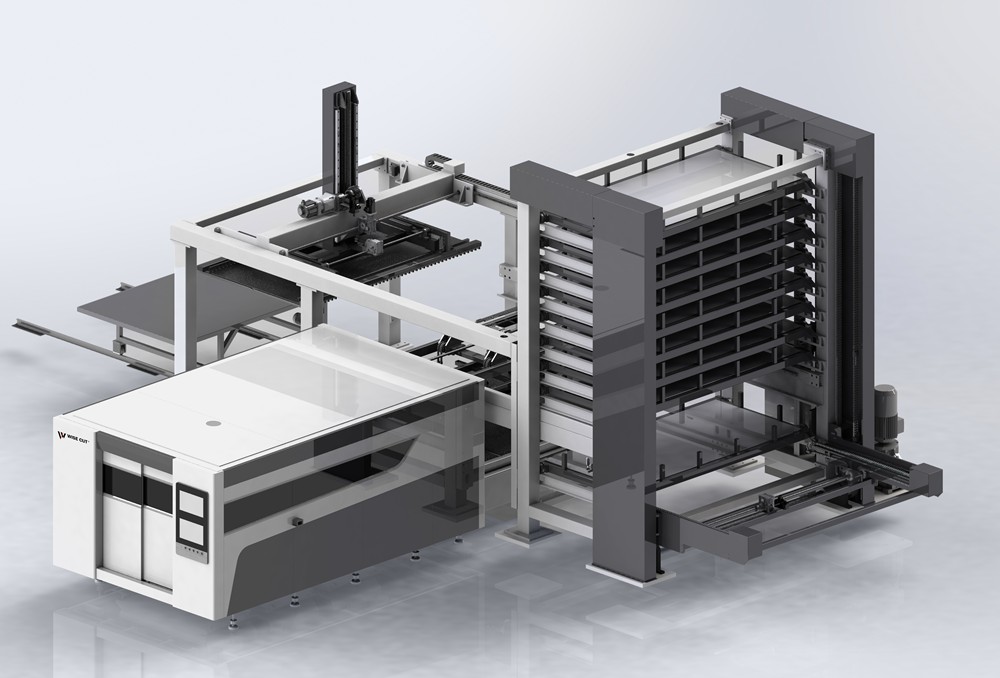

WiseCut, headquartered in Tianjin, operates a modern manufacturing complex of three integrated buildings combining production, R&D, and post-sales service. As a CE-certified high-tech enterprise, WiseCut adheres to strict ISO 9001 standards and emphasizes innovation, precision, and reliability across its product lines.

Its flagship model, the WT-3015 Fiber Laser Cutting Machine, is equipped with a Raycus CE-version 3000W laser source, BOCI BLT-310 auto-focus cutting head, French Schneider electronic components, and a Taiwan YYC helical rack for high-speed, high-accuracy motion control. The machine delivers stable performance and exceptional cutting precision for carbon steel, stainless steel, aluminum alloy, copper, and titanium.

With over 1,000 installations in more than 20 countries, WiseCut serves diverse sectors including rail transit, automotive manufacturing, construction machinery, and agricultural equipment. Supported by 24/7 global technical service and engineer on-site response within 48 hours, the company continues to expand its international footprint as a reliable supplier meeting European quality benchmarks.

2: LinTech Precision

The company provides flatbed systems with Bosch motors that are imported from Germany. The Suzhou facilities operate under ISO9001 certification to perform rigorous quality control procedures. The company provides easy-to-use ERP system integration through its plug-and-play solution.

3: NeoLaser Robotics – Leader in Smart Factory Integration

Their AI-powered CNC platforms enable cloud-based updates and real-time diagnostic functions. The company operates in more than 40 countries while its machines receive TUV SÜD certifications and feature RoHS-compliant wiring harnesses.

4: LaserEase – Compact CO₂ Solutions Provider

The company focuses on providing affordable solutions for small to medium-sized enterprises that need signage and apparel production equipment. Their desktop CO₂ series includes EN-compliant circuit protection and simple USB controller integration capabilities.

5: TitanPhoton – High-Speed Fiber Lasers Manufacturer

The 30kW models from this company operate with Siemens SINUMERIK systems and meet all CE requirements for operation. These machines operate best in shipbuilding facilities and structural steelwork shops which need to perform deep cutting operations.

6: AutoFab Machinery – Automotive Sector Specialist

Their robotic arm-integrated cutters exist as custom solutions for OEMs who need precise cutting operations under EN ISO 13849 safety standards.

7: DualCore Systems – Dual-Purpose Hybrid System Innovator

The system unites CO₂ and fiber heads into one gantry structure. The product follows EU RoHS directives for hazardous substances because more environmentally focused customers now demand this standard.

8: ProtoSteel – Entry-Level Industrial Machine Maker

The company targets its entry-level customers through workshops which help them transition from handheld plasma cutting to automated cutting systems. The company provides CE documentation with every delivery to help customers navigate customs procedures.

9: SkyVolt AeroTech – Aerospace & Defense Application Expert

The company specializes in micro-tolerance laser machining which follows all requirements of the EU Machinery Directive (2006/42/EC). The company serves as a trusted partner for all Tier-1 aerospace suppliers operating throughout Europe.

10: CloudTrack CNC – Cloud-Based Monitoring System Developer

The platform provides cloud-based dashboard solutions which support OPC UA communication protocols. The system follows GDPR guidelines for data management which supports EU organizations in their IT security compliance efforts and enables them to perform predictive equipment maintenance.

Key Comparison: What Buyers Should Evaluate

Certification & Compliance Documentation Review

Buyers need to ask for Declaration of Conformity documents together with CE certificates that Notified Bodies with accreditation have issued. The technical files containing EN ISO risk assessments should be requested by buyers during their due diligence process.

Core Components Sourcing & Assembly Quality

The following list shows elements which affect system reliability throughout extended operation periods.

| Component | Preferred Source | Notes |

| Laser Head | Raycus/IPG | Power range from 1kW to 30kW |

| CNC Controller | FSCUT/Siemens | Check firmware version |

| Servo System | Yaskawa/Panasonic/Fuji | Impacts axis stability |

| Chiller Unit | Hanli | Crucial for temperature control |

| Rack & Rail | YYC & HIWIN (Taiwan) | Affects movement accuracy |

The YYC Helical Rack and Pinion system from Rack-TAIWAN YYC provides high precision transmission with high speed operation and stable performance.

How to Choose a Reliable Supplier

Evaluating Production Capacity and Lead Time Reliability

The delivery schedule depends on whether the supplier manufactures frames internally or sends them to external manufacturers. The speed at which replacement parts reach European clients depends on inventory management systems because this determines the duration of breakdown-related downtime.

Assessing After-Sales Support Infrastructure

European buyers need to evaluate these service performance indicators:

- Are on-site technicians available locally?

- What is the standard lead time for spare parts?

- How clear are warranty terms?

WiseCut operates its machines with built-in after-sale centers which provide service to both Chinese customers and international clients. The WiseCut factory located in Tianjin operates an after-sale service system.

Verifying Customer Feedback & International Presence

Trade platforms including Alibaba Verified Suppliers and industry events like EMO Hannover and EuroBLECH provide access to trustworthy reviews of Chinese manufacturers who display CE-compliant systems at their exhibitions.

Emerging Trends for 2025

Increased Demand for Eco-Friendly Manufacturing Solutions

The market shows growing interest in sustainability data which leads customers to choose products made from recyclable alloys and equipped with energy-efficient standby modes instead of traditional models.

FAQ

Q1: What makes WiseCut stand out among Chinese laser cutting machine suppliers?

A: The WiseCut factory based in Tianjin operates from three buildings which unite manufacturing operations with research and development activities and post-sales support functions. The factory provides CE-certified fiber lasers which incorporate high-end components including Raycus CE version lasers and French Schneider electrical parts.

Q2: Are Chinese laser cutting machines accepted in the EU?

A: The majority of companies today follow CE marking regulations and EMC directives and EN ISO standards and GDPR-compliant software practices for their smart monitoring systems.

Q3: What’s the difference between fiber laser and CO₂ laser machines?

A: Fiber lasers provide fast and accurate metal cutting capabilities for stainless steel and brass materials but CO₂ lasers operate best on non-metal substances including wood and acrylic while failing to cut through thick metal sheets.

Q4: What are critical components to check before buying?

A:The evaluation should concentrate on four main areas which include Raycus/IPG laser sources and FSCUT/Siemens CNC systems and Yaskawa/Fuji servo motors and YYC & HIWIN rack & rail quality and Hanli chillers as cooling units.